Nigeria’s small-scale farmers and agro-processors can use electricity from mini-grid solutions to overcome the country’s poor electricity supply and its negative impacts on their activities and economics, a new report has shown.

The report produced by the US Power Africa Nigeria Power Sector Program (PA-NPSP), disclosed that there are immediate opportunities to use clean mini grid electricity to electrify these agricultural businesses.

Specifically, the PA-NPSP Agricultural Productive Use Stimulation in Nigeria explained that rice and grain flour milling as well as cassava grating are the three prevalent agricultural processing activities primed to benefit from productive use of mini grid solutions in the country.

The three are considered staple food in Nigeria. Moreover, agriculture contributed about 21.91% to the country’s Gross Domestic Products (GDP) in 2019 but has also suffered from its poor electricity supply.

However, the Power Africa report showed that there are existing opportunities to electrify agricultural productive uses, and how these opportunities can be developed through commercial business models to help the small-scale agro-based activities overcome the power challenge.

Using filed data from Kaduna and Cross Rivers, it explained that mini grid solutions could replace fossil-fuelled and manual processing activities for several agricultural value chains in rural Nigerian communities. These opportunities, it added are commercially viable for processors, who can reduce costs and increase revenue, and are equally beneficial for mini-grid economics.

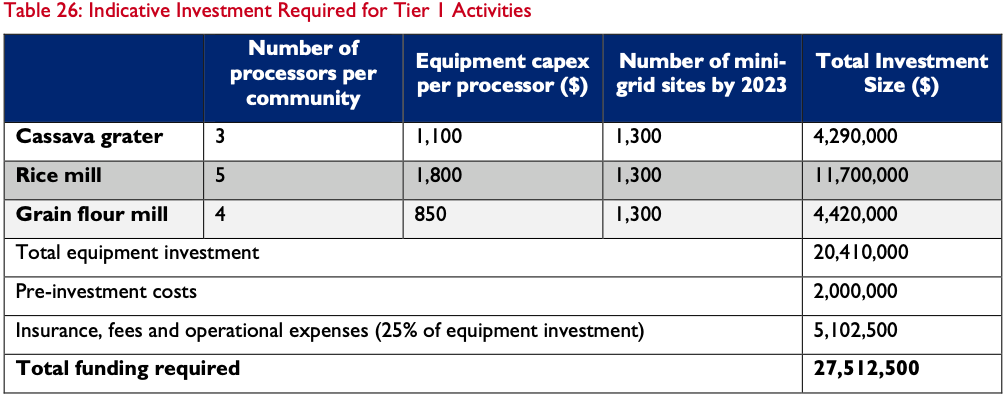

To jump start the electrification of productive use alongside mini grids for these agro-based activities, the report stated that substantial financial investment would be required, but the total amount – about $27.5 million, it added is within the capabilities of existing funding programs in the country.

Cassava, grain and rice processing

According to the report, mini grid solutions can support productive activities in cassava, grain and rice farming.

“Cassava is a critical staple food grown at high volumes throughout Nigeria. Nearly all cassava is mechanically processed before consumption. Cassava grating is a leading candidate for electrification,” said the report.

It further noted that nearly all cassava products require peeled roots to be grated into a soft mash amenable to further processing, and nearly all grating is mechanical in Nigeria.

“The diesel lister engine is the costliest part of the mechanical grinder, and there is potential opportunity to displace fossil fuels while saving on fuel cost,” it added.

In terms of market size, it explained that cassava farming is a nearly $10 billion dollar industry in Nigeria, with an estimated 60 million metric tons of the tuber produced each year. This, it suggests provides logical economic argument for deploying mini grid.

“The Nigerian cassava value chain is extremely complex, and the crop can be processed into hundreds of different final products. However, 85–90% of cassava goes to a few processed foods: gari (a toasted granular meal), fufu/akpu/lafun (fermented pastes) and cassava starch.

“Cassava grating can be readily electrified through new electrical graters or electric motor retrofits. Mechanical cassava grating was present in most cassava-producing communities included in the field survey, all powered by petrol or diesel motors,” the report further said.

For maize and rice, it stated that milling amongst others provide opportunity for mini grid deployment.

“Most existing small-scale processers are millers who produce corn meals and flours. Most maize milling is already mechanized, and electric. Mini-grid-run maize threshing may provide a revenue stream for developers.

“Maize is typically mechanically threshed by businesses based outside mini-grid communities, but customers show a willingness to utilize a local fee-for-service thresher in the community center, it added while stating that other opportunities for maize flour production activities requiring mini grid supports include winnowing and mechanical grain drying.

It said that: “Rice milling is a top-tier opportunity for electrification with mini-grids, and there’s strong national demand for the service.”

According to it, an estimated 80% of domestic rice consumed in Nigeria is milled at the local level by processors, while threshing and mechanical grain drying are opportunities for mini grids.

Other productive uses

Beyond the opportunities in cassava, grain and rice milling, the report listed other agro-based activities that could maximize outputs with mini grid electricity.

“Aquaculture provides food and livelihoods for millions of Nigerians. Catfish account for 70% of fish farm production, while tilapia comprise an additional 10%.

“Water pumping and aeration are cost-competitive to operate with mini-grid electricity, saving 25% of operating costs compared to diesel pumps. However, the prevalence of ground-sourced water pumping is dependent upon the local watershed, and aerated aquaculture is not yet common in mini-grid-suitable communities,” it said.

Additionally, it stated that refrigeration and freezing have more potential near natural fisheries, where freshly caught fish must often be preserved before sale in markets some distance from the point of capture.

The report stated that fish smoking or drying is another opportunity for mini grid use in aquaculture, with women who dominate fish smoking subjected to negative health impacts from the use of traditional wood fires.